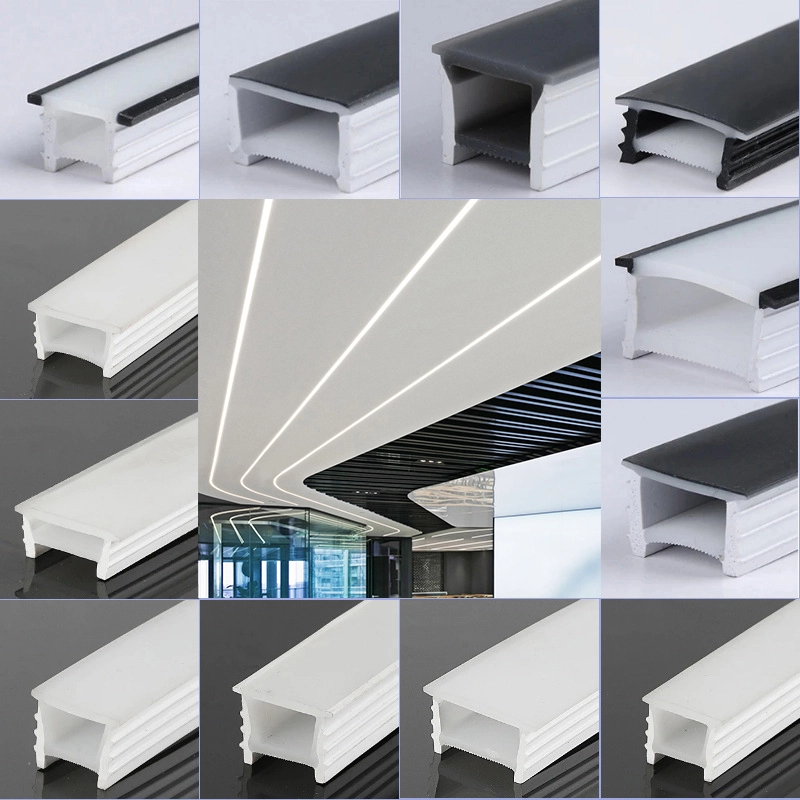

Wholesale Bendable Silicone LED Strip Channel Waterproof Recessed Profile for Large Projects

Product Overview

Our LED Silicone Profile is developed to meet the functional and commercial demands of modern LED strip lighting systems. It serves as a protective enclosure while enhancing light continuity, making LED installations more refined, durable, and visually consistent across different environments.

Designed with practical installation and long-term use in mind, this silicone profile supports both standardized and project-based lighting solutions.

● Flexible Cutting & Bending

● Extreme Durability

● Flame Retardant Safety

● Eco-Friendly & Non-Toxic

Product Advantages

Why Choose Our LED Silicone Tubing?

Material Performance You Can Rely On

Manufactured using high-quality silicone compounds, the profile maintains stable physical properties during prolonged LED operation. It withstands mechanical stress, environmental exposure, and frequent handling without compromising shape or performance, making it suitable for high-traffic and long-running lighting applications.

Consistent Visual Results

The internal structure of the silicone profile is optimized to manage light output efficiently. By controlling diffusion and reducing visual interruptions, it helps create a clean, continuous lighting line that aligns with contemporary architectural and commercial design standards.

Adaptable for Diverse Project Requirements

The flexibility of the silicone housing allows installers to work efficiently across straight runs, curves, and transitions. This adaptability reduces installation complexity and provides designers with greater freedom when planning custom lighting layouts.

Production Stability for B2B Supply

As a factory-oriented supplier, we focus on repeatability, dimensional consistency, and scalable manufacturing. This ensures our LED Silicone Profiles meet the expectations of wholesalers, contractors, and lighting brands seeking dependable products for ongoing projects and distribution.

Why Choose 100% Pure Silicone LED Tubing?

Choosing 100% silicone LED tubing is a practical decision driven by real application demands and market experience. In architectural, commercial, and outdoor lighting projects, LED systems often operate for long hours and are exposed to heat, UV, moisture, and environmental stress. Pure silicone maintains stable flexibility and structural integrity under these conditions, unlike mixed materials that may harden, discolor, or fail over time.

From a market perspective, professional buyers increasingly prefer 100% silicone because it delivers consistent light diffusion, longer service life, and lower maintenance costs. It supports modern lighting designs that require smooth, continuous light lines and reliable performance across different climates. Overall, 100% silicone tubing provides better project reliability, protects brand reputation, and reduces long-term operational risk for B2B lighting projects.

Why Choose Flame-Retardant, High-Temperature Resistant LED Silicone Tubing?

Choosing flame-retardant, high-temperature resistant LED silicone tubing is essential for applications where safety, durability, and long-term performance are critical. In commercial buildings, public spaces, architectural façades, and outdoor installations, LED strips often operate continuously and generate heat in enclosed or concealed areas. Flame-retardant silicone helps reduce fire risk and improves overall system safety, meeting the expectations of modern building and project standards.

From a market perspective, contractors, developers, and lighting brands increasingly specify high-temperature resistant materials to avoid premature failure, costly maintenance, and liability risks. Silicone tubing that maintains flexibility and structural stability under heat ensures consistent light output and protects LED strips over time. As projects become larger and regulations more stringent, flame-retardant, heat-resistant LED silicone tubing has become a preferred choice for reliable, compliant, and future-proof lighting solutions.

FAQ